Yc-8701a Mkpuchi seramiiki Nano nke na-anaghị ekpuchi mmiri nke ọma

Akụkụ ngwaahịa na ọdịdị ya

(Mkpuchi seramiiki otu akụkụ

Mmiri mmiri odo odo na-enweghị agba ruo na-acha ọcha

Agba YC-8701: doro anya, ọbara ọbara, odo, acha anụnụ anụnụ, ọcha, wdg. Enwere ike ime mgbanwe agba dịka ihe ndị ahịa chọrọ si dị.

Ihe mkpuchi dị irè

Ígwè na-abụghị nke carbon, ígwè anaghị agba nchara, ígwè a kpụrụ akpụ, titanium alloy, aluminum alloy, copper alloy, iko, seramiiki, nkume e ji aka rụọ, gypsum, simenti, seramiiki eriri, osisi, wdg.

Okpomọkụ dị mkpa

Ogologo oge okpomọkụ ọrụ: -50℃ ruo 200℃.

Nguzogide okpomọkụ nke mkpuchi ahụ ga-adị iche dabere na iguzogide okpomọkụ nke ihe dị iche iche. Na-eguzogide oyi na okpomọkụ na mkpọtụ okpomọkụ.

Atụmatụ ngwaahịa

Ihe mkpuchi Nano bụ otu ihe, anaghị emebi gburugburu ebe obibi, ọ naghị egbu egbu, ọ dị mfe itinye ma nwee arụmọrụ kwụsiri ike.

2. Mkpuchi ahụ agafeela ule SGS na ule FDA na United States, ọ bụkwa nke nri.

3. Mkpuchi nano nwere nnukwu ntinye aka. Site na ntinye aka, mkpuchi, njupụta, mkpuchi na nhazi ihe nkiri elu, ọ nwere ike ịrụ ọrụ nke ọma na nke ọma iji nweta mkpuchi akụkụ atọ na arụmọrụ mmiri.

Ike mkpuchi ahụ nwere ike iru awa 6 ruo awa 7, nke na-eguzogide iyi, na-adịgide adịgide, na-eguzogide acid na alkali, na-eguzogide nchara, na-eguzogide ọgwụ nnu, na-egbochi ịka nká. Enwere ike iji ya mee ihe n'èzí ma ọ bụ n'ọnọdụ ọrụ dị elu ma na-ekpo ọkụ nke ukwuu.

5. Mkpuchi ahụ na-arapara nke ọma na ihe mkpuchi ahụ, ike njikọ ya karịrị 5 MPa.

6. Mkpuchi nano-inorganic nwere arụmọrụ mkpuchi eletriki dị mma.

7. Mkpuchi ahụ n'onwe ya anaghị ere ọkụ ma nwee ụfọdụ ihe ndị na-egbochi ire ọkụ.

8. Mkpuchi ahụ na-eguzogide oyi na okpomọkụ dị elu ma nwee ezigbo iguzogide okpomọkụ.

9. Enwere ike ịgbanwe agba ndị ọzọ ma ọ bụ ihe ndị ọzọ dịka ihe ndị ahịa chọrọ si dị.

Oghere ngwa

1. Paịpụ, oriọna, arịa, graphite.

2. Mmiri mmiri dị irè maka ime ụlọ ịsa ahụ ma ọ bụ kichin, sink ma ọ bụ ọwara, wdg.

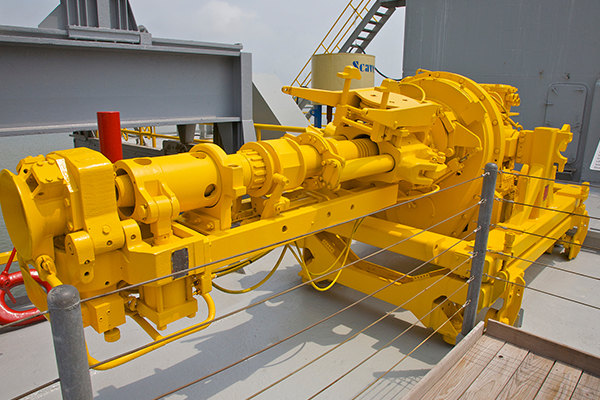

3. Ihe ndị dị n'okpuru mmiri (nke a na-eme ka ọ dabara na mmiri oké osimiri), ụgbọ mmiri, ụgbọ mmiri, wdg.

4. Ihe ịchọ mma ụlọ, ihe ịchọ mma arịa ụlọ.

5. Ime ka ihe ndị na-egbochi ire ere nke bamboo na osisi sie ike ma melite.

Ụzọ ojiji

1. Nkwadebe tupu e kpuchie ya

Nchacha agba: Nchacha site na ihuenyo nzacha 400-mesh wee debe ya n'akụkụ mgbe emechara nzacha ahụ.

Nhicha ihe dị n'okpuru ala: Iwepụ mmanụ na mkpụcha nchara, ime ka elu dị nro ma sie ike, ime ka ájá dị ọcha site na ọkwa Sa2.5 ma ọ bụ karịa, a na-enweta mmetụta kachasị mma site na iji ájá mee ihe na corundum 46-mesh (corundum ọcha).

Ngwa mkpuchi: Dị ọcha ma kpọọ nkụ, ekwesịghị imetụ mmiri ma ọ bụ ihe ndị ọzọ aka, ma ọ bụghị ya, ọ ga-emetụta irè nke mkpuchi ahụ ma ọ bụ ọbụna mee ka ọ ghara ịdị irè.

2. Usoro mkpuchi

Ịgba: Fesa ya n'ọnọdụ okpomọkụ ụlọ. A na-atụ aro ka ọkpụrụkpụ ịgba ya dị ihe dị ka micron 50 ruo 100. Mgbe e mechara agbaze ájá, hichaa ihe eji arụ ọrụ ahụ nke ọma na ethanol na-anaghị agbaze ma jiri ikuku akpọnwụọ kpoo ya. Mgbe ahụ, usoro ịgba ya nwere ike ịmalite.

3. Ngwaọrụ mkpuchi

Ngwa mkpuchi: Egbe ịgba (dayameta 1.0). Mmetụta atomization nke egbe ịgba obere dayameta ka mma, mmetụta ịgba ya dịkwa mma. A chọrọ compressor ikuku na nzacha ikuku.

4. Ọgwụgwọ mkpuchi

Ọ nwere ike ịgwọ ọrịa site n'okike, a pụkwara ịhapụ ya ihe karịrị awa iri na abụọ (ịkpọnwụ elu n'ime awa abụọ, ịkpọnwụ nke ọma n'ime awa iri abụọ na anọ, na ịgbaze seramiiki n'ime ụbọchị asaa). Ma ọ bụ tinye ya n'ime oven ka ọ kpọọ nkụ n'okike ruo nkeji iri atọ, wee sie ya na ogo 150 maka nkeji iri atọ ọzọ ka ọ gwọọ ngwa ngwa.

Ihe ndetu

1. Dabere na ọnọdụ ọrụ dị iche iche, a pụrụ itinye mkpuchi ahụ na usoro ọgwụgwọ mkpuchi ahụ a kpọtụrụ aha n'elu ugboro abụọ (imeghachi usoro ahụ dum dị ka otu ngwa) ma ọ bụ ihe karịrị ugboro abụọ iji nweta mmetụta kachasị kwụsie ike nke dabara na ọnọdụ ọrụ n'ezie.

2. Awụpụla ihe mkpuchi nano a na-ejighị eme ihe site na ngwugwu mbụ ahụ n'ime ya. Jiri ákwà nzacha 200-mesh tee ya ma debe ya iche. A ka nwere ike iji ya ma emechaa.

Nchekwa ngwaahịa: Debe n'ime akpa mechiri emechi, ebe ìhè na-anaghị apụta. Debe ya n'ebe okpomọkụ dị site na 5℃ ruo 30℃. Ndụ nchekwa nke mkpuchi nano bụ ọnwa isii. A na-atụ aro ka e jiri ya mee ihe n'ime otu ọnwa mgbe emepechara ya maka nsonaazụ ka mma. (Nanoparticles nwere ike dị elu n'elu, ọrụ dị elu ma na-adịkarị mfe ịgbakọta.) N'okpuru ọrụ nke ndị na-agbasa na ọgwụgwọ elu, nanoparticles na-anọgide na-akwụsi ike ruo oge ụfọdụ.

Ihe Ndetu Pụrụ Iche

1. A na-eji ihe mkpuchi nano a naanị. Etinyela ihe ọ bụla ọzọ (karịsịa mmiri), ma ọ bụghị ya, ọ ga-emetụta arụmọrụ nke ihe mkpuchi nano nke ukwuu ma mee ka ọ gbawaa ngwa ngwa.

2. Nchedo onye ọrụ: Dịka nchekwa ahụ n'oge a na-etinye mkpuchi nkịtị, zere ọkụ na-emeghe, ọkụ eletrik na ọkụ eletrik n'oge usoro mkpuchi ahụ. Maka nkọwa zuru ezu, biko lee akụkọ MSDS nke ngwaahịa a.

Pụrụ iche nye Youcai

1. Nkwụsi ike teknụzụ

Mgbe anwalechara ule siri ike, usoro teknụzụ seramiiki nke nanocomposite nke aerospace na-anọgide na-akwụsi ike n'okpuru ọnọdụ dị oke njọ, na-eguzogide okpomọkụ dị elu, ujo okpomọkụ na nchara kemịkalụ.

2. Teknụzụ mgbasa Nano

Usoro mgbasa pụrụ iche a na-ahụ na a na-ekesa nanoparticles n'otu aka ahụ n'ime mkpuchi ahụ, na-ezere njikọta. Ọgwụgwọ interface dị irè na-eme ka njikọ dị n'etiti ihe ndị ahụ dịkwuo mma, na-eme ka ike njikọ dị n'etiti mkpuchi ahụ na ihe ndị dị n'okpuru ya dịkwuo mma yana arụmọrụ zuru oke.

3. Njikwa mkpuchi

Usoro nhazi ziri ezi na usoro nhazi dị iche iche na-eme ka arụmọrụ mkpuchi ahụ nwee ike ịgbanwe agbanwe, dịka ike, iguzogide iyi na nkwụsi ike okpomọkụ, na-emezu ihe achọrọ maka ngwa dị iche iche.

4. Àgwà nhazi Micro-nano:

Mkpụrụ seramiiki Nanocomposite na-ekpuchi mkpụrụ micrometer, mejupụta oghere ndị ahụ, na-emepụta mkpuchi dị oke njọ, ma na-eme ka obere ihe na iguzogide nchara dịkwuo mma. Ka ọ dị ugbu a, mkpụrụ nanoparticles na-abanye n'elu ihe mejupụtara ahụ, na-emepụta interphase metal-seramik, nke na-eme ka ike njikọ na ike zuru oke dịkwuo mma.

Ụkpụrụ nnyocha na mmepe

1. Nsogbu nke mgbasawanye okpomọkụ: Ọkwa mgbasawanye okpomọkụ nke ihe ígwè na seramiiki na-adịkarị iche n'oge usoro ikpo ọkụ na oyi. Nke a nwere ike ibute mmepe nke obere mgbawa na mkpuchi n'oge usoro ịgbagharị okpomọkụ, ma ọ bụ ọbụna iwepụ. Iji dozie okwu a, Youcai emepụtala ihe mkpuchi ọhụrụ nke ọnụọgụ mgbasawanye okpomọkụ dị nso na nke ihe mejupụtara ígwè ahụ, si otú a na-ebelata nrụgide okpomọkụ.

2. Nguzogide nke ujo okpomọkụ na mkpọtụ okpomọkụ: Mgbe mkpuchi elu ígwè na-agbanwe ngwa ngwa n'etiti okpomọkụ dị elu na nke dị ala, ọ ghaghị inwe ike iguzogide nrụgide okpomọkụ nke na-esi na ya apụta na-enweghị mmebi. Nke a chọrọ ka mkpuchi ahụ nwee ezigbo iguzogide ujo okpomọkụ. Site n'ịkwalite obere nhazi nke mkpuchi ahụ, dị ka ịbawanye ọnụọgụ nke njikọ usoro na ibelata nha ọka, Youcai nwere ike ime ka ujo okpomọkụ ya ka mma.

3. Ike njikọ: Ike njikọ dị n'etiti mkpuchi ahụ na ihe mkpuchi ígwè dị oke mkpa maka iguzosi ike na ogologo oge nke mkpuchi ahụ. Iji mee ka ike njikọ ahụ dịkwuo mma, Youcai na-ewebata oyi akwa etiti ma ọ bụ oyi akwa mgbanwe n'etiti mkpuchi ahụ na ihe mkpuchi ahụ iji melite ike mmiri na njikọ kemịkalụ n'etiti ha abụọ.